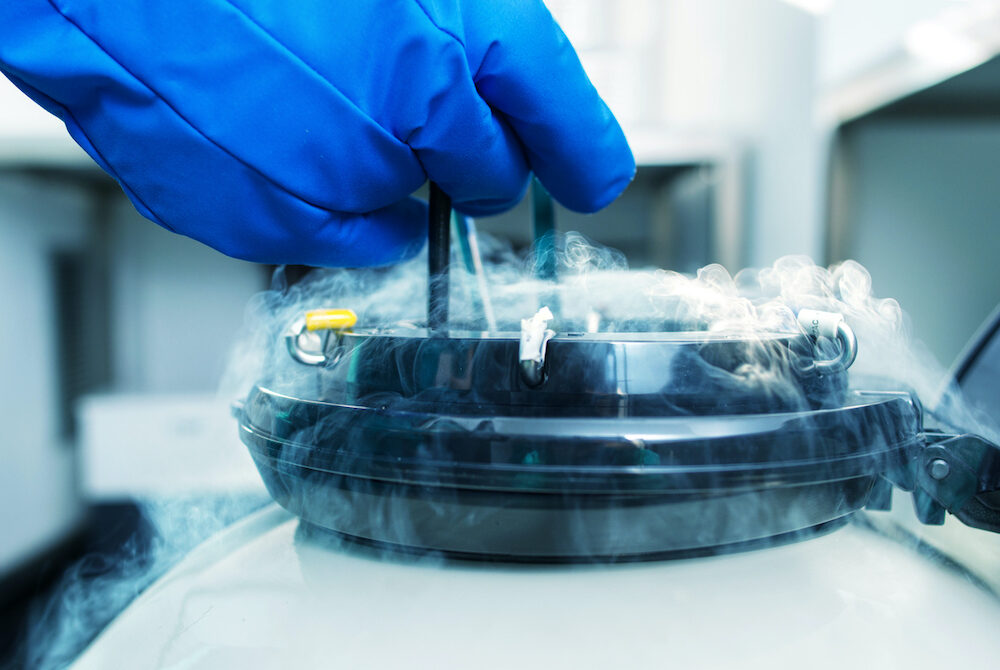

During transportation, it is essential to monitor the temperature of dry ice to ensure that your goods are transported in the best conditions. Dry ice, also known as frozen carbon dioxide, is often used to keep products at a constant temperature during transportation. It is especially useful when transporting perishable goods such as food, pharmaceuticals and medical samples.

Dry ice is very cold and can bring the temperature of your products well below freezing. However, it can also be dangerous if not treated properly. To ensure that your products are transported safely and efficiently, closely monitor the temperature of the dry ice during transport.

Different methods of monitoring temperature

There are several ways to monitor the temperature of dry ice during transport. One of the most common methods is the use of data loggers. These small devices record temperature during transport and store this data for later use. This way you can check the temperature of the dry ice and detect any abnormalities.

Another way to monitor the temperature of dry ice is through the use of temperature indicators. These indicators change color when the temperature falls outside the desired range. This way you can quickly see if anything is wrong with the temperature of the dry ice and address any problems quickly.

Remember, monitoring the temperature of dry ice during transport is essential for the safety and efficiency of your goods. Be sure to use proper methods to monitor temperature and act quickly if problems arise. By staying on top of the temperature of your dry ice during transport, you can ensure that your goods arrive at their destination in the best possible condition.