Everything you need to know about the Innolabel Data Logger for Temperature Measurements

When it comes to temperature monitoring and quality control, the Innolabel data logger from TimeStrip is an absolute must-have. This innovative tool helps businesses and organizations accurately monitor, record, and analyze temperature data. In this blog, we discuss everything you need to know about the Innolabel data logger, from the technology behind the device to the benefits it offers for various industries.

What is an Innolabel data logger?

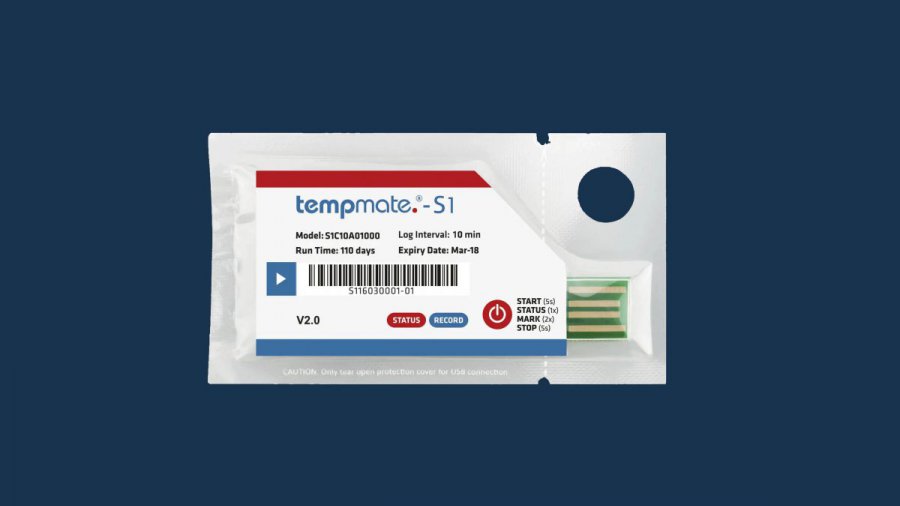

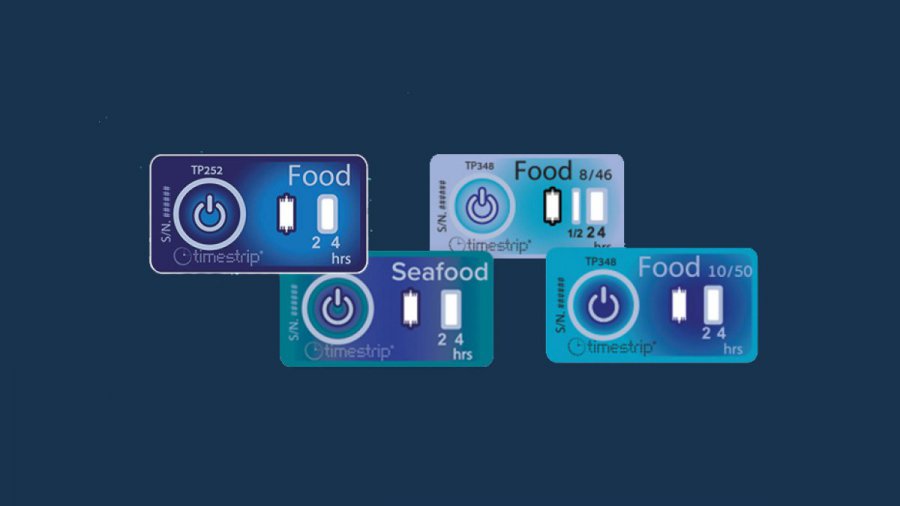

The Innolabel temperature data logger is a compact and sophisticated device specifically designed to measure and record temperatures in various environments. These data loggers are ideal for use in industries where temperature plays a crucial role, such as: In Food Industry, Pharmaceutical Industry, Transportation and Logistics and Healthcare. With the Innolabel data logger you can easily track temperatures over a specific period of time. This is essential for ensuring the quality and safety of products and processes.

How does an Innolabel data logger for temperature work?

The Innolabel data logger works with advanced sensors that record real-time temperature data. The device is usually placed in strategic locations, such as refrigerators, freezers or transport vehicles. The logger collects data and stores it in its internal memory, which you can then read via a computer or mobile app.

Important features of the Innolabel data logger are:

- Accurate sensors: Records temperatures accurate to the degree

- Durable design: Resistant to extreme conditions, such as freezing or heat

- User-friendly interface: Easy to set up and read out

- Data export options: Data can be exported to Excel, PDF or cloud-solutions.

Advantages of the Innolabel data logger

Using an Innolabel data logger for temperature offers numerous advantages for businesses that depend on temperature monitoring. Here are some key reasons why companies choose this technology:

- Quality assurance

A stable temperature is essential to ensure the quality of products. Think of foods that must remain fresh or medicines that should not exceed a certain temperature. With an Innolabel data logger you prevent quality loss and guarantee safety. - Compliance with regulations

In many industries, temperature logging is mandatory to comply with laws and regulations, such as HACCP in the food industry. The Innolabel data logger makes it easy to comply with these requirements by generating accurate reports. - Cost savings

By detecting deviations in temperature in a timely manner, you can take action quickly and prevent damage to products or equipment. This saves costs in the long run. - Convenience and flexibility

The data logger is compact, lightweight and easy to use. Whether you manage a small warehouse or run a large transportation company, the Innolabel data logger adapts to your needs. - Real-time monitoring

Some models allow you to view real-time data through a linked app or software. This is especially useful in transportation and logistics, where constant monitoring is critical.

Applications of the Innolabel data logger

The versatility of the Innolabel data logger makes it suitable for a wide range of applications. Here are some examples of how this technology is used in practice:

- Transportation of perishable goods: Ensure that food products remain refrigerated during transport and comply with required temperature regulations.

- Drug storage: Monitor temperatures in pharmacies, hospitals and laboratories to ensure drug effectiveness.

- Cold stores and freezers: continuously monitor temperatures in large storage areas.

- Agriculture and horticulture: Protect crops and seeds by controlling temperatures in greenhouses and storage areas.

Tips for using an Innolabel data logger temperature

To make the best use of the Innolabel data logger for temperature, here are some tips:

- Placement is critical: Place the temperature data logger in a strategic location where it can collect accurate data. Avoid direct sunlight or places with many temperature fluctuations.

- Calibrate regularly: Make sure the data logger is properly calibrated to ensure accurate readings. This can be done periodically by the manufacturer.

- Check the battery: Many Innolabel data loggers run on batteries. Check them regularly to ensure that the device can keep measuring continuously.

- Use associated software: Make use of the software or app that comes with the data logger. This allows you to analyze data, generate reports and chart trends.

- Store data properly: Store collected data securely. This can be important for audits or internal controls.

Why choose the Innolabel data logger?

The Innolabel temperature data logger is distinguished by its reliability, ease of use and versatility. Companies that depend on temperature control rely on this technology to keep their processes running smoothly. Whether you work in the food industry, pharmaceutical sector or logistics, the Innolabel data logger offers a customized solution.